3 Core processes in SAP S/4HANA for Manufacturing Logistics

Introduction

At a time when manufacturing processes are constantly evolving, companies are faced with a multitude of challenges and opportunities.A large variety of product models, a high volume of externally procured goods or the need to move to areas outside the factory premises are not only business challenges for companies, but also IT challenges.

SAP has recognized these challenges and is opening up new process possibilities for its customers with the SAP S/4HANA for Manufacturing Logistics add-on solution for mapping processes in the manufacturing industry.

We would like to share our know-how with you: In this article, you will learn more about the three main processes supported by SAP S/4HANA for Manufacturing Logistics.

About SAP S/4HANA for Manufacturing Logistics

SAP S/4HANA for Manufacturing Logistics is integrated into SAP S/4HANA and extends the scope of SAP Extended Warehouse Management (SAP EWM) and SAP Transportation Management (SAP TM) by providing seamless process integration between incoming goods inspections, warehousing, production and external storage.

SAP S/4HANA is a prerequisite for the use of SAP S/4HANA for Manufacturing Logistics.

The solution offers the following three main functions:

Tugger Train for Production Supply – Extension for SAP EWM

Shuttle –

Extensions for SAP EWM and SAP TM

Inbound Cargo Registration –

Extension for SAP TM

Tugger Train in SAP EWM

Tugger train application scenario

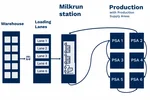

In the manufacturing and automotive industry, the use of tugger trains plays a crucial role in the production supply process. Tugger trains, consisting of towing vehicles and trailers with pallets (handling units) or fan wagons, facilitate the movement of materials between the warehouse and various production supply areas and ensure a continuous supply of components to support the manufacturing processes.

Tugger trains consist of a towing vehicle and several trailers that carry container units (HUs), e.g. small load carriers (KLTs) or large load carriers (GLTs). These tugger trains are used to transport materials between different stages of the production process. SAP S/4HANA for Manufacturing Logistics provides the necessary functions to support the tugger train process in SAP EWM.

The tugger train process in SAP EWM includes several steps that contribute to the efficient movement of materials in the manufacturing environment. These steps include:

1. Creation of the Order for Production Supply

The process begins with the creation of a production supply order, which is triggered by just-in-time (JIT) call-offs, production material requests (PMR), outbound deliveries orders (ODOs), stock transfers or rebookings. These requests form the basis for initiating the production supply process.

2. Picking Preparation

As soon as the supply order is generated, a route ID/tour ID must be assigned. The tour is planned and picking tasks are created.

3. Picking Execution

Picking tasks include removing the required handling units from storage and placing them on trailers, for example. The picking process is optimized to ensure accurate and timely material removal.

4. Loading

After picking, the container units are loaded onto the designated trailers. This step can be controlled by the system or carried out manually, depending on the specific logistical requirements.

5. Delivery to the Production Supply Area

The loaded tugger train delivers the container units to the designated production supply areas to ensure that the right materials are available for the production processes.

6. Unloading of Handling Units

In the production supply area, the container units are unloaded from the trailers and made available for use in the production processes.

7. Return to the Loading Areas

Once unloading is complete, the tugger train returns to the loading areas to prepare for the next tour.

Important Master Data for the Tugger Train in SAP EWM

- Route-ID: A defined route in SAP EWM specifies the path that the tugger train follows in the warehouse and in the production areas. Similar to a bus route with several stops, the route specifies the sequence of production supply areas (PSAs) that the tugger train visits, controlled by SAP EWM. The route configuration includes parameters such as tour creation strategies, maximum container units per tour and PVB assignments.

- Tour-ID: Tours are execution data that correspond to specific time windows during which the route train executes the predefined route. Tours are generated based on the route master data.

Summary Tugger Train Process in SAP EWM

The tugger train solution in SAP S/4HANA for Manufacturing Logistics brings significant benefits to the manufacturing and automotive industries in the operation of their logistics through SAP EWM. By seamlessly integrating processes between warehousing and production, the solution improves the efficiency of material flow, production supply and resource utilization. The optimized tugger train process, which is controlled by route and tour concepts integrated in SAP EWM, ensures a continuous flow of materials and supports smooth production processes. With „SAP S/4HANA for Manufacturing Logistics“ , companies can gain greater control over their production supply processes in SAP EWM and ultimately contribute to improving the operational flow of materials.

Shuttle Process in SAP EWM

Shuttle Process Application Scenario

Modern supply chain management involves complex warehouse and transportation processes. In scenarios where buildings of the same SAP EWM warehouse number are geographically separated, a seamless solution in SAP EWM is required to enable the transportation of goods while ensuring proper documentation and visibility. This transportation often requires external carriers and printed shipping documents. The SAP EWM standard does not initially offer a solution to address this challenge.

To solve this problem, an integration between SAP EWM and SAP TM is used in „SAP S/4HANA for Manufacturing Logistics“ , which provides direct access to SAP TM documents such as freight orders and freight units in SAP EWM. Based on this integration, TM is able to print freight documents and bill external carriers. Both SAP EWM and SAP TM are also able to track the goods that are currently in transit.

The shuttle process in SAP EWM and SAP TM comprises several steps to ensure the seamless and traceable movement of goods:

1. Event for Triggering the Stock Transfer

Stock transfers are created to initiate the transportation of goods. Two options are available: Ad-hoc shuttle or scheduled shuttle.

2. Creation of Warehouse Tasks

Based on the triggering event for the movement, picking tasks (WTs) are generated and picking is carried out.

3. HU placement in the staging/loading area

Selected handling units (HUs) are placed in designated staging/loading areas.

4. Execution of Loading of the Shuttle

The HUs are loaded onto the shuttle using the radio frequency user interface (RFUI). This process ends with the printing of the delivery documents.

5. Transport of the Shuttle to the other Building

The shuttle is physically transported between the buildings.

6. Execution of Unloading of the Shuttle

The RFUI in SAP EWM facilitates the unloading of HUs from the shuttle after arrival.

7. Internal Stock Movement

… to the final destination in the warehouse.

Important Master Data / Customizing in SAP EWM

Layout-oriented storage control for Shuttle: The layout-oriented storage control (LOSC) for the shuttle configures the loading and unloading of the shuttle as well as the transportation routes using public roads. It is important to note that the standard layout-oriented storage control (LOSC) in SAP EWM has a higher priority than the shuttle-specific LOSC. If an entry is identified in the standard layout-oriented storage control, the system automatically bypasses the shuttle-specific LOSC.

Summary Shuttle Process in SAP EWM

The integration of SAP EWM and SAP TM for the internal transport of goods via the shuttle process represents a significant advance in the optimization of supply chain operations. By seamlessly connecting warehouse and transportation functions, this solution improves documentation, visibility and overall process efficiency, helping to increase customer satisfaction.

Inbound Cargo Registration in SAP TM

Inbound Cargo Registration Application Scenario

Production facilities with a large volume of inbound goods often use a centralized receiving office for pre-qualification, data management and control of inbound cargo. The Inbound Cargo Registration (ICR) solution is a modern application based on the Advanced Shipping and Receiving solution (SAP TM and SAP EWM).

Process Flow Inbound Cargo Registration in SAP TM

Inbound Cargo Registration (ICR) in SAP TM is a streamlined user interface that offers, for example, better data transparency or an easier way to package delivery items. The process steps can vary depending on the process design and requirements. However, the basis is always the standard solution "Advanced Shipping and Receiving".

1. Receipt of Delivery and Transport Notifications via EDI

The ICR combines received data where necessary and possible.

2. Checking and Changing EDI Data

In Inbound Cargo Registration, you can check and correct the EDI data received directly in the business application in SAP TM.

3. Packing

The ICR includes individual and mass creation of handling units, including the use of the "Unified Package Builder" (UPB).

4. Control of Inbound Transports

Loading point and/or storage door can be assigned and customized.

5. Goods Receipt Posting

Posting the goods receipt from the ICR application in SAP TM.

Important Master Data / Customizing in SAP TM

As already mentioned, the ICR is based on the "Advanced Shipping and Receiving" solution. This means that you can only process transport management documents if all shipping/loading points are relevant for "Advanced Shipping and Receiving".

Summary Inbound Cargo Registration in SAP TM

The ICR's optimized user interface with its improved functionality such as packing/repacking and the use of the Unified Package Builder in SAP TM or EDI error handling provides a modern and effective solution for production facilities that have to deal with significant volumes of incoming goods.

Bottom Line

In this article, we presented the SAP S/4HANA for Manufacturing Logistics solution with its best-practice processes tugger train, shuttle and inbound cargo registration. The solution presented, with its close integration of SAP TM and SAP EWM, makes a significant contribution to the digital mapping of intralogistics with lean and integrated storage and transportation processes for companies in the manufacturing industry.

We hope you enjoyed reading this article. If you have any further questions, please do not hesitate to contact us using the contact form below.